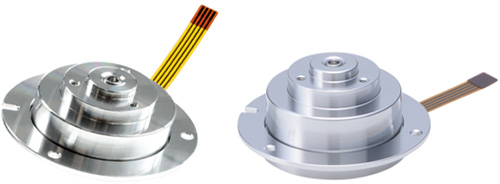

FDB Motor

The BLDC FDB motor is combining the advantages of a BLDC (Brush Less DC) motor and cutting edge FDB (Fluid Dynamic Bearing) technology.

Features

A BLDC motor is brushless, the commutation is done electronically. There is no need for brushes, as the torque is a function of the electronic action of the brushless motor on the commutator. This means is that a brushless motor has fewer parts that can wear out and there is never any need to be concerned about the condition of the brushes. A BLDC motor is longer lasting and more reliable than their brushed counterparts. It's a very effective motor with an optimized electromagnetic design for noise, vibration and jitter which last for the long-term.

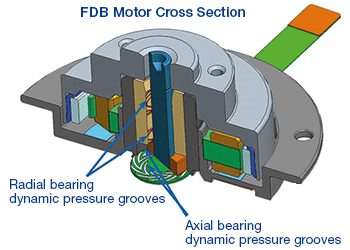

The FDB (Fluid Dynamic Bearing) eliminates the limited precision of ball bearings, minimizing the non-repeatable run out, lowering acoustic noise level, and improving the reliability. The FDB was originally developed for hard disk drives and their ultra-precise mechanical requirements and long working life.

This hydrodynamic bearing system (FDB) is the right choice for your high precision application.

* The bearing which works by hydro dynamic pressure is generally expressed "Fluid Dynamic Bearing" or "FDB" in technical field.

The BLDC FDB motor offers superior performance in terms of:

- extremely quiet and accurate running

- low vibration

- low run out (NRRO below 40 nm)

- low level of noise

- extremely long-lasting, since there a no wear parts

- high speed up to 15.000 rpm

- wobble error < 3"low

- energy consumption

Applications

- Hard Disk Drives

- LiDAR

- Virtual Reality: motion tracking

- 2D & 3D Scanner

- Fans

- DLP Projector

- Respiratory Equipment

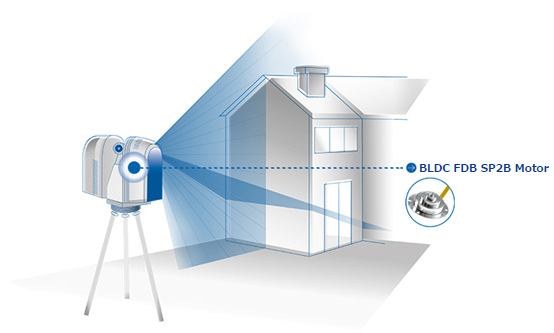

Measurement Technology

With its wide temperature range, the BLDC FDB SP2B motor is ideally suited for indoor and outdoor applications. The FDB technology provides high density and accuracy. The small size and the high stiffness both fit perfectly when it comes to mobile application usage. Thanks to the combination of a brushless DC motor with the cutting-edge technology of fluid dynamic bearing, high running and scanning precision are guaranteed.

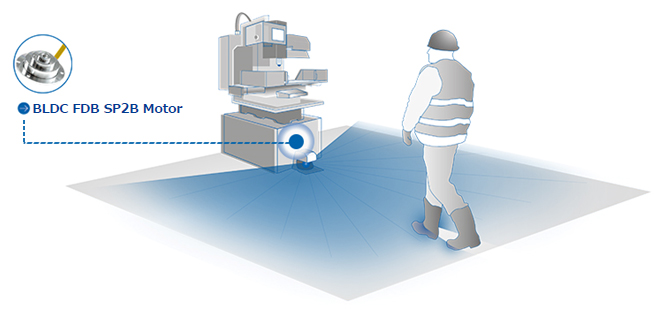

Safety Technology

High accuracy, low vibration, a wide field of vision as well as high axial and radial stiffness are only a few of the numerous virtues of our FDB motor in the area of safety technology. The motor allows high density and a wide viewing angle. Thanks to the compact design also smaller constructions in this application area are possible. The fluid dynamic bearing comes without the limited precision of ball bearings and minimizes the non-repeatable run out to optimize the steadiness.

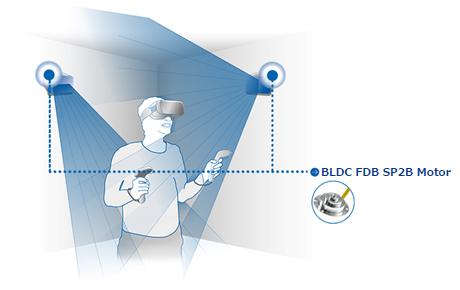

Consumer Electronics

The BLDC FDB SP2B motor provides the link to the real world. Due to its extremely quiet running and its accuracy, the level of noise is minimized. Furthermore the FDB motor allows a high density and turns virtual content into reality. The fluid dynamic bearing fulfils the high precision standards in consumer electronics. Since there are no wear parts, a long service life is guaranteed.

Product Data

| Item | Contents |

|---|---|

| Development |

|

| Manufacturing |

|

| Commenced Operation | in 2017 |

Application

- Portable amusements

- Projectors

- Data projectors

- Projectors for home theater systems

- Medical Equipment

- Security Cameras

- LiDAR

Links to Product Site

- Link to Online Catalogue site

- MinebeaMitsumi Product Site

Contact Us

Japan [ Sales Headquarters MinebeaMitsumi Inc. ]

| FAX | 81-3-6758-6760 |