2025

May 14, 2025

MINEBEA MITSUMI Inc.

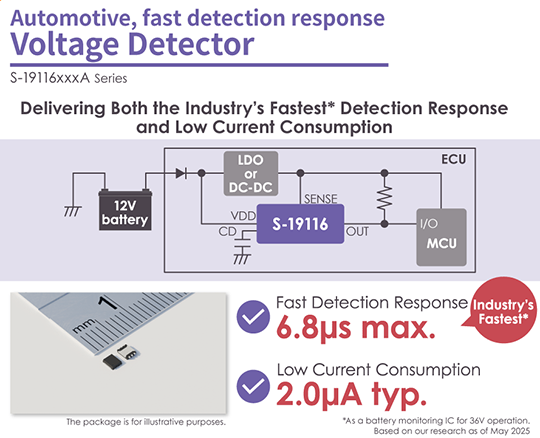

ABLIC launches S-19116 Series Slashes Detection Time by 92% with Industry-Leading 6.8μs Response

- Industry's fastest automotive high-withstand voltage detector -

MinebeaMitsumi Group

Green Products

ABLIC (President: Seiji Tanaka, Head Office: Minato-ku, Tokyo; hereinafter "ABLIC"), a group company of MinebeaMitsumi Inc., today launched the S-19116 Series, a new automotive high-voltage detector featuring the industry's fastest(*1) detection response time of max. 6.8μs while achieving ultra-low current consumption of 2.0μA typ.

While industry standard voltage monitoring response times typically range from tens to hundreds of μs when detecting overvoltage faults, the new S-19116 Series achieves an industry-leading detection response time of max. 6.8μs, representing approximately 92% reduction compared to conventional products. Additionally, this detector significantly reduces system standby current and comes in an ultra-compact HSNT-6 (1.96×2.46×t0.5mm) package, meeting the growing demands for space optimization in today's automotive equipment.

As an example of functional safety(*2) measures to mitigate the impact of potential failures, overvoltage protection is essential when supplying voltage from a battery through a regulator to MCUs(*3) and sensors. The countermeasure involves detecting irregularities such as overvoltage in the regulator output using a voltage detector, and safely resetting the MCU. However, during this process, the voltage supplied from the regulator to the MCU and sensors continues to rise, potentially exceeding the ECU's voltage tolerance and creating a risk to system safety and functional safety compliance.

This has been a significant technical trade-off in addressing this challenge. While increasing the detection response speed of the voltage monitoring function can mitigate the safety risk, faster detection response typically increases current consumption, which in turn increases the system's standby current(*4) —a critical concern for engineers working to minimize power consumption.

The S-19116 Series significantly enhances functional safety for automotive applications by delivering improvements in both detection speed and current consumption performance.

- (*1) As a 36Voperation automotive voltage detector. Based on our research as of May 2025

- (*2) Functional safety: The incorporation of functional innovations to maintain an acceptable level of safety

Reference

- (*3) MCU:Micro Controller Unit

- (*4) Standby current: Quiescent current, or current that flows even when the ignition is turned OFF

Major Features

- 1. Fast voltage detection response speed and low current consumption

- Achieves both the industry's fastest(*1) detection response time, a 92% reduction compared to industry's conventional products, and low current consumption of 2.0μA.

Increasing the overvoltage detection response speed makes it so that monitoring of voltage increases occurs quicker, ensuring faster output of detection signals to the microcontroller and thereby improving system safety. The low current consumption of 2.0μA during operation also contributes to lower standby current for the overall system. - 2. The ultra-small package contributes to a smaller footprint

- Use of the HSNT-6 (1.96 mm×2.46 mm×t0.5 mm) ultra-small automotive package allows for an approximately 20% smaller footprint than conventional products.

- 3. The SENSE pin to which monitoring voltage is input allows for a wide range of input voltages from -30 V to 45 V

- Negative voltage can be applied to the SENSE pin. Because the SENSE pin can be connected upstream of the reverse current protection diode installed each ECU, the product can also be used for applications requiring high-accuracy, direct monitoring of I/G and battery voltage.

- 4. Automotive application quality

- The product undergoes three-temperature tests (low temperature, normal temperature, and high temperature). It is also planned to be made compliant with the AEC-Q100 reliability and quality assessment tests by the AEC (Automotive Electronics Council). PPAP (Production Part Approval Process) compliance is also planned. The product can be used in the severe environments of automobile applications.

Major Specifications

| • Operation voltage range: | 3.0 V to 36.0 V |

|---|---|

| • Voltage detection range: | 8.0 V to 24.0 V |

| • Detection voltage accuracy: | ±1.5% (Ta=-40°C to +125°C) |

| • Hysteresis width: | Selectable from 0%, 2.3%, 5%, 9% |

| • Current consumption during operation: | 2.0µA typ. |

| • Detection response time: | 6.8µs max. |

| • Release delay time: | 10ms typ. (CD=3.3 nF) |

| • Operating temperature: | -40 to +125°C |

| • Packages: | SOT-23-5, HSNT-6(2025) |

| • AEC-Q100 compliant | |

| • PPAP support available | |

Application Examples

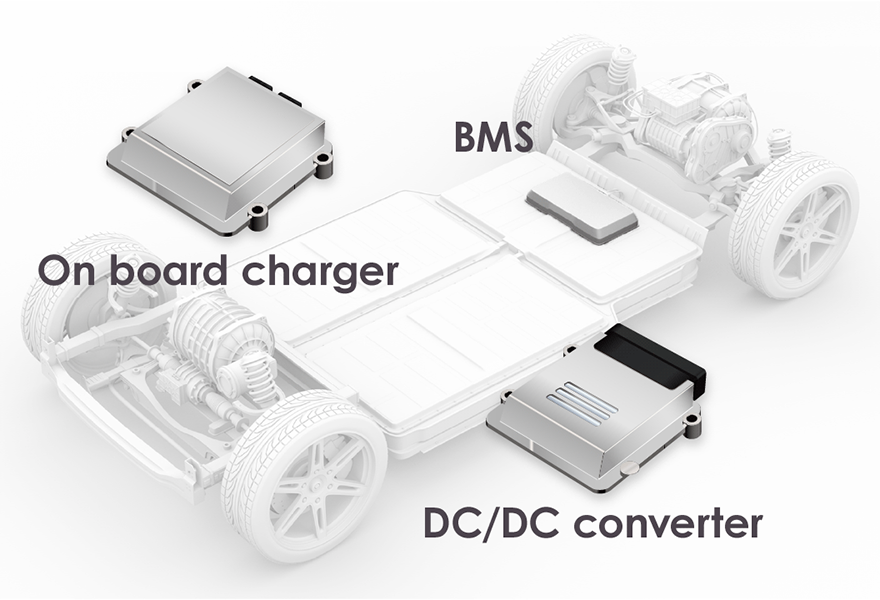

Automotive applications (engines, transmissions, suspensions, ABS, EV/HEV/PHEV, etc.)

Automotive battery voltage detection

Key Applications

- DC/DC Converter

- On Board Charger (OBC)

- ADAS Domain Controller

- Battery Management System (BMS)

- Inverter

Product Details

Website

https://www.ablic.com/en/semicon/![]()

This product has been certified as a MinebeaMitsumi Group "Green Product" for its outstanding contribution to the environment.

| Contacts | ABLIC Inc. Masae Onuma E-mail: pr@ablic.com https://hub.ablic.com/en/pr-inquiry?rf=support Newsroom: www.mynewsdesk.com/ablic |

|---|

Product information, contact and other context are subject to change without prior notice.