2012

(Posted Oct. 2012)

Japan's First Manufacturer Specialized in Miniature Ball Bearings

Minebea's history stretches back about 60 years to 1951, when the company began as Japan's first specialty manufacturer of miniature ball bearings with about 10 employees and a small factory.

At the time, miniature ball bearings were used mostly in aircraft instrumentation. Just after the Second World War, however, there were no Japanese manufacturers capable of producing this type of highprecision manufactured parts. The founders of Minebea decided to embark on the manufacture of miniature ball bearings based on the belief that aircraft demand would increase in the future, and that Japan needed the technological capability to manufacture this type of high-precision product. The specialty of the product as well as the lack of adequate manufacturing equipment posed significant challenges for the founders, who relied on trial and error to overcome obstacles.

Despite the challenges, Minebea successfully established its manufacturing technology in the late 1950s thanks to the efforts of Japanese engineers. After the high-quality products were recognized in the U.S. market, Minebea's sales began to take off. In 1963, the company constructed the Karuizawa Plant and equipped it with state of the art machinery. This established the company's modern manufacturing foundation by enabling mass production of high-quality products. To respond to rising demand for Minebea products worldwide, the company expanded business to Singapore in 1972 and then to Thailand and China. Today, the Minebea Group maintains eight ball bearing manufacturing plants worldwide, with approximately 10,000 employees involved in the business, and a monthly production of some 250 million ball bearings.

The company continued to grow through trial and error with President Seiichiro Takahashi at the helm

Expansion work on the Karuizawa Plant in the 1960s

Column "What is Ball Bearings?"

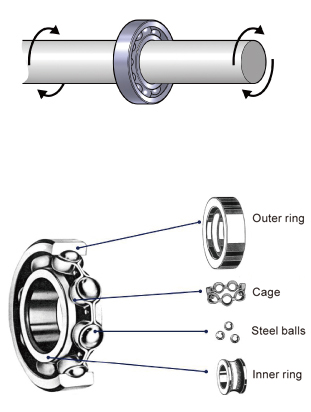

The Function of Ball Bearings

From car axles to electric fans and hard disc drives (HDDs), ball bearings are used in a wide array of machines for rotary motion. Ball bearings support rotary parts and reduce friction to facilitate the smooth operation of machines. The size of ball bearings can range from smaller than a grain of rice—small enough to fit inside a wristwatch—to over one meter in diameter for factory and power plant applications. Minebea specializes in the manufacture of miniature and small-sized ball bearings with an outer diameter of 30mm or less.

Structure of Ball Bearings

Ball bearings are comprised of four major parts: a large ring (outer ring), a small ring (inner ring), balls between the rings (steel balls), and a cage to prevent the balls from hitting each other. The modern structure dates back to around 1500, when Leonardo da Vinci invented ball bearings to reduce friction against the axles of horsedrawn carts. For more than 500 years, the ball bearing has been defined by this simple structure.

The Precision of a Ball Bearing

The main function of a ball bearing is to reduce friction and facilitate smooth rotation of an axis. Modern ball bearings test the very limits of precision. As an example, one of the key elements to making an ultra-precise ball bearing is the degree to which the groove where the balls roll can be made into a perfect circle. Minebea has achieved ultra-precision groove manufacturing which reduces the range of error from a perfect circle to one-one hundred thousandth of a millimeter.