Initiatives for Preventing Global Warming Back Number (2013)

Back to Latest Initiatives for Preventing Global Warming

Basic Approach

The Minebea Group recognizes that the international issue of global warming, along with the related issues of soaring energy prices and abnormal climatic conditions, pose a significant threat to the sustainability of its business activities.

In response, each office and plant in the Minebea Group is proactively promoting energy efficiency initiatives in order to combat global warming after having completed formulating the main measures for their sites. Additionally, our Energy Conservation Promotion Committee, which is made up of representatives of all our business units, promotes the sharing of knowledge and technologies accumulated from past activities along with case studies on exemplary energy-efficient initiatives. The sharing of this wisdom among the Group's business units is bolstering the entire Group's approach to global warming prevention.

Results of FY2012 Initiatives

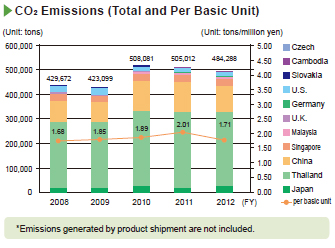

The Minebea Group's emissions of CO2 in FY2012 totaled 484,288 tons, 4% less than in FY2011. In terms of basic units of production, CO2 emissions declined 15% over FY2011 to 1.71 tons per million yen of production. The cause of this decrease was the large improvement in productivity compared with levels prior to the Thai floods.

The Minebea Group's emissions of CO2 in FY2012 totaled 484,288 tons, 4% less than in FY2011. In terms of basic units of production, CO2 emissions declined 15% over FY2011 to 1.71 tons per million yen of production. The cause of this decrease was the large improvement in productivity compared with levels prior to the Thai floods.

In FY2012, the Group also made headway in determining the CO2 emissions from Group logistics activities. As a result, we are able to determine the amount of CO2 emissions generated from overseas sites' land, sea, and air logistics operations, as we have done for domestic sites. Moving forward, we will continuously take measures to improve the accuracy of data collection.

Initiatives at Offices

ISO 50001 Employee Training in Thailand

ISO 50001 training in Thailand

In Thailand, the largest manufacturing base for the Group, we are implementing energy management measures based on the ISO 50001 international standard with the aim of managing and continually improving our energy consumption. In FY2012, we provided training on these measures to employees who are spearheading the efforts.

Training Program Contents

- ISO 50001 Fundamentals and Requirements

(April 2012; 80 participants) - ISO 50001 Internal Auditor Development

(May 2012; 61 participants) - Energy Efficiency Awareness by Outside Energy Experts

(June 2012; 51 participants)

Environment, Energy, CSR, Health and Safety Exhibits (Thailand)

In November and December each year, Minebea Thailand promotes a travelling exhibit on the environment, energy, CSR, health and safety at each of its plants to raise employee awareness on these issues.

In FY2012, the exhibit focused on the following global warming prevention-related topics.

- Environmental and energy initiatives from fiscal 2010 through FY2012

- Biodiversity conservation

- Renewable energy

- Corporate social responsibility and related activities

Week-long environment, energy, CSR, and health and safety exhibit at the Bang Pa-in Plant

Initiatives at Offices

At our offices, we are taking a wide range of measures to reduce CO2 emissions, including promoting cool business attire and turning off unnecessary lights in summer, along with holding no-overtime days.

In January 2013, we acquired a new building to house our Tokyo Head Office. We are making strides instituting a higher level of global warming countermeasures at the new building.

Initiatives Related to Logistics and Transport

Modal Shift Initiatives

Loading and unloading containers directly on and off vessels

The Minebea Group is building a logistics network between Japan and China which minimizes CO2 emissions by optimizing the shipping methods for products, machinery, materials and other traded goods. The shipments between Shanghai and Hakata, Japan utilize high-speed ferry, while the shipments between Hakata and Tokyo utilize Japan Railways (JR) freight trains or regional sea shipment. The transport scheme also utilizes high-speed ferries (RORO vessel*1) which use trucks to load and unload containers directly onto and from vessels instead of large cranes. Compared to the previous Shanghai-Tokyo logistics network utilizing only standard cargo vessel shipments, this new shipping method has enabled us to both shorten lead times and minimize energy consumption (CO2 emissions) compared with air freight shipments.

*1 Roll-on & roll-off (RORO) vessel; High-speed ferry capable of rapidly loading and unloading truck containers without using large harbor cranes.

Future Issues and Goals

The Minebea Group will continue to advance its measures to prevent global warming. As a medium-term goal, by FY2015 we plan to reduce CO2 emissions per basic unit of production by 5% compared with FY2010, or 1% annually.

In terms of long-terms goals for 2030 and 2050, we will monitor the Intergovernmental Panel on Climate Change (IPCC) and policies in countries around the world in formulating our initiatives.