Initiatives for Preventing Global Warming Back Number (2012)

Back to Latest Initiatives for Preventing Global Warming

Basic Approach

The Minebea Group recognizes that the international issue of global warming, along with the related issues of soaring energy prices and abnormal climatic conditions, pose a significant threat to the sustainability of its business activities.

In response, each office and plant in the Minebea Group is proactively promoting energy efficiency initiatives in order to combat global warming. Additionally, each site is striving to develop representative initiatives which can be deployed across the Group and has completed implementing initiatives. In January 2010, we formed the Energy Conservation Promotion Committee in order to take global warming prevention measures to the next level across the Group. The committee is comprised of members from every business unit, enabling the sharing of accumulated knowledge, technology, and best energysaving practices. The spread of knowledge across the business units is strengthening the Group's overall ability to implement global warming prevention measures.

Results of FY2011 Initiatives

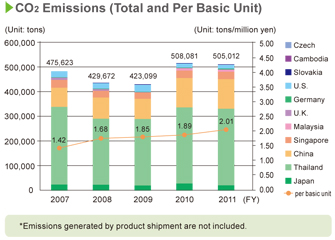

The Minebea Group's emissions of CO2 in FY2011 totaled 505,012 tons, 0.6% less than in FY2010. In terms of basic units of production, CO2 emissions increased 6.3% over FY2010 to 2.01 tons per million yen of production. The cause of this increase was the negative impact of the Great East Japan Earthquake and the Thai floods on productivity in comparison with FY2010.

The Minebea Group's emissions of CO2 in FY2011 totaled 505,012 tons, 0.6% less than in FY2010. In terms of basic units of production, CO2 emissions increased 6.3% over FY2010 to 2.01 tons per million yen of production. The cause of this increase was the negative impact of the Great East Japan Earthquake and the Thai floods on productivity in comparison with FY2010.

In FY2011, the Group also made headway in determining the CO2 emissions from Group logistics activities. We developed a system to determine the level of emissions from each domestic site on a monthly basis, as well as a system to compile data on air and sea logistics for overseas sites.

Initiatives at Offices

Response to Power Shortages Following the Great East Japan Earthquake

A "green" curtain used to save power (Fujisawa Plant)

The shortage of electric power in eastern Japan following the Great East Japan Earthquake of March 11, 2011 has become a serious issue for the nation. In response, the Minebea Group has actively implemented power conservation measures at its Fujisawa, Matsuida, and Omori plants, Tokyo head office, and sales offices within the Tokyo Electric Power Company's service area.

The following are examples of these measures:

- Shifting daytime production to nighttime

- Reducing the number of lights used

- Shutting down air conditioners and lighting during peak energy consumption hours in the afternoon

- Consolidating work space in order to reduce areas cooled by air conditioners

- Allowing employees to wear polo shirts and other cool work attire

- Setting up plant curtains near windows to absorb heat

Award for project to raise efficiency of plant and office air conditioning systems (Thailand)

In 2011, Minebea took part in a project sponsored by the Thai Ministry of Energy to raise the efficiency of air conditioning systems in manufacturing plants and offices. The Bang Pa-in Plant was recognized with an award for its success in finding effective ways to improve efficiency.

The Plant's major initiatives are listed below.

Major Improvement Measures

- Adjustment of refrigerators' cold water flow volume

- Reduction in number of refrigerator units in operation

- Replacement of the cooling tower's filling material, etc.

Receiving the award

Commemorative plaque

Initiatives Related to Logistics and Transport

Modal Shift Initiatives

Shipping containers are directly loaded and

unloaded in Shanghai

Minebea uses high-speed ferries between Shanghai and Hakata to export and import products, machinery and equipment, materials and other goods between China and Japan, and uses Japan Railway freight trains and domestic vessels between Hakata and Tokyo. This transportation strategy greatly reduces lead times compared to using conventional freight vessels between Shanghai and Tokyo. It also substantially reduces energy consumption (CO2 emissions) relative to air transportation.

High-speed RORO* ferries can load and unload containers using trucks instead of large harbor cranes. This contributes substantially to lead time reduction while saving energy.

* Roll-on & roll-off (RORO) vessel; High-speed ferry capable of rapidly loading and unloading truck containers without using large harbor cranes.

Future Issues and Goals

The Minebea Group has set a target of reducing its CO2 emissions per unit of production by 1% each year in comparison to FY2010, for a total reduction of 5% by FY2015. For FY2012, we have set a goal of establishing a system by which we can regularly report the amount of CO2 emissions from logistics operations worldwide.

We will also take measures with a long-term outlook for 2030 and 2050, monitoring the Intergovernmental Panel on Climate Change (IPCC) and the policies of various countries.