Initiatives for Reducing Impacts on the Environment Back Number (2011)

Back to Latest Initiatives for Reducing Impacts on the Environment

Basic Approach

Factory effluents and emissions can be a source of water, air, and soil pollution that poses a threat to local communities. The Minebea Group seeks to coexist with the regions in which it operates, and believes that striving to reduce the emission of substances with an impact on the environment is an ongoing responsibility.

To comply with environmental laws in each country and region, each Minebea Group plant sets its own standards that exceed legal requirements, and monitors them on a daily basis. Additionally, employees conduct environmental patrols to ensure that there are no anomalous conditions, including leakage, unusual odors, high noise levels, or vibration in the vicinity of the plant.

Results of FY2010 Initiatives

As exemplified by its mass-production plants in Thailand and China, the Minebea Group's goal is to recycle effluents generated within the plant to the maximum degree possible, without discharging them outside the plant (Plant Zero-effluent System).

However, at the present time not all Minebea Group plants have introduced this system, and at some plants wastewater is discharged into rivers and streams after being cleaned to required levels in wastewater treatment facilities on the plant premises. These plants adhere to environmental laws of the countries and localities in which they operate, and independently monitor such wastewater discharges, including regular testing for such metrics as pH (Note 1), COD (Note 2), BOD (Note 3), SS (Note 4), and n-hexane extractions (Note 5) (oil content).

In FY2010, no anomalous monitored values were reported by any plant. In addition, no complaints relating to these metrics were received.

- Note 1. pH: A scale indicating whether substances are acidic or alkaline. pH7 is neutral. pH values below 7 indicate increasing acidity, while values above 7 indicate increasing alkalinity.

- Note 2. COD (chemical oxygen demand): The amount of oxygen consumed to oxidize organic substances (pollution) in water. COD measurement takes less time than BOD measurement, but is less reliable. COD is generally used as a metric in wastewater management for sea, lake, and marsh waters.

- Note 3. BOD (biological oxygen demand): The amount of oxygen required for bacteria to consume and decompose organic matter (pollution) in water. Higher values indicate greater degrees of pollution. Measurement takes several days. BOD is generally used to observe effluent water in rivers.

- Note 4. SS (suspended solids): The volume of substances suspended in water. The high the number, the greater the degree of water pollution.

- Note 5. n-hexane extractions: A substance called n-hexane, extracted from oils and detergents that are difficult to volatilize in water. In this report they signify mineral oils.

Plant Initiatives

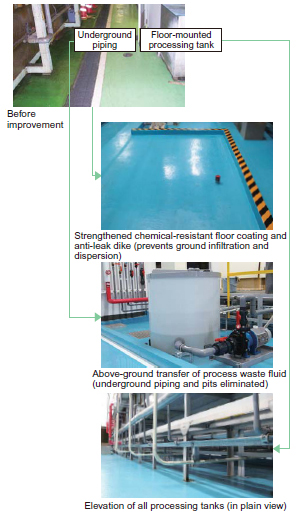

Mitigating Risk to Soil and Groundwater (Fujisawa Plant)

Surface processing during the manufacturing process is carried out with water as well as a variety of chemical substances. Since nearly all of these chemical substances are liquids, such events as natural disasters, accidents, or mistaken use may result in spattering or leakage of fluids to the floor of the facility. In addition, buried piping and underground drainage pits for waste fluids can degrade and release effluents to the environment in such events as an earthquake.

Surface processing during the manufacturing process is carried out with water as well as a variety of chemical substances. Since nearly all of these chemical substances are liquids, such events as natural disasters, accidents, or mistaken use may result in spattering or leakage of fluids to the floor of the facility. In addition, buried piping and underground drainage pits for waste fluids can degrade and release effluents to the environment in such events as an earthquake.

Consequently, in view of the possibility of an emergency we have moved all facilities for surface treatment fluids, including piping and storage structures, from below ground to floor-mounted locations, and processing tanks and fluid piping are in plain view. In addition to moving the facilities to floor-mounted locations, the underlying floor surface was coated with a strengthened, chemical-resistant coating, and the area enclosed by an anti-leak dike.

Damage Control Training for Chemical Substance Leaks (Shanghai Plant)

Accidental leakage of chemical substances is a major risk in conducting machining operations. The Chemical Substances Group of the Environmental Safety Committee at Minebea's Shanghai Plant prepares for the possibility of such accidents by carrying out periodic damage control training for chemical substance leaks.

Regular training maintains plant employee skills in such areas as the appropriate and prompt emergency use of liquid chemical absorbent, which is always available on site for the prevention of chemical substance leakage, as well as measures to clean up absorbent afterward.

Damage control training for chemical substance leaks under way at the Shanghai Plant

Management of PRTR-controlled Substances (Japan)

In accordance with the Pollutant Release and Transfer Register (PRTR) Law, all of our places of business in Japan manage the amounts of PRTR-controlled substances used and transported.

Reported Results for FY2010

| Control number | Substance name | Volume handled | Emission Volumes | Transfer volumes | ||

|---|---|---|---|---|---|---|

| Air | Water | Landfill | Waste | |||

| 31 | Antimony trioxide | 1.8 | - | - | - | 0.0903 |

| 185 | HCFC-225 | 1.05 | 0.99 | - | - | 0.06 |

| 232 | Nickel compounds | 0.8 | - | 0.01 | - | 0.34 |

| 384 | 1-bromopropane | 26.65 | 24.53 | - | - | 2.12 |

Initiatives against Soil and Groundwater Contamination

Cleanup was completed at

the Kanegasaki Plant

In the past, the Minebea Group has caused soil and groundwater pollution at some of its places of business with chlorinated organic solvents containing volatile organic compounds (VOC). Cleanup work of contaminated plants and plant sites is proceeding under the Minebea Group's auspices. Cleanup for one such location, the Kanegasaki Plant in Iwate Prefecture, was completed in March 2011.

Future Issues and Goals

The Minebea Group continues to conduct business operations in compliance with environmental law in Japan and around the world, and is proceeding with cleanup work in areas where it has caused environmental contamination in the past.